The BDC3030 is a perfect balance of speed and power, mixing viscosities up to 50,000 mPa.

The high torque capabilities of the BDC1850 enable mixing of creams as thick as 90,000 mPa.The BDC6015 offers the widest range of speed settings, from 40 to 6,000 rpm.Adjust pH: Lastly, adjust the pH as needed to finalize the batch.Ĭaframo’s high torque line of overhead stirrers has been a popular choice for research and development labs in the cosmetics and personal care industries.Temperature-sensitive ingredients: Now that the mixture is cool, mix in any needed ingredients such as preservatives, fragrances, and coloring.Continue to mix until the mixture cools down to 30☌. Cool down: After 20 minutes of mixing, replace the propeller impeller with an anchor impeller.At 80☌, use a propeller impeller to mix the two for at least 20 minutes.

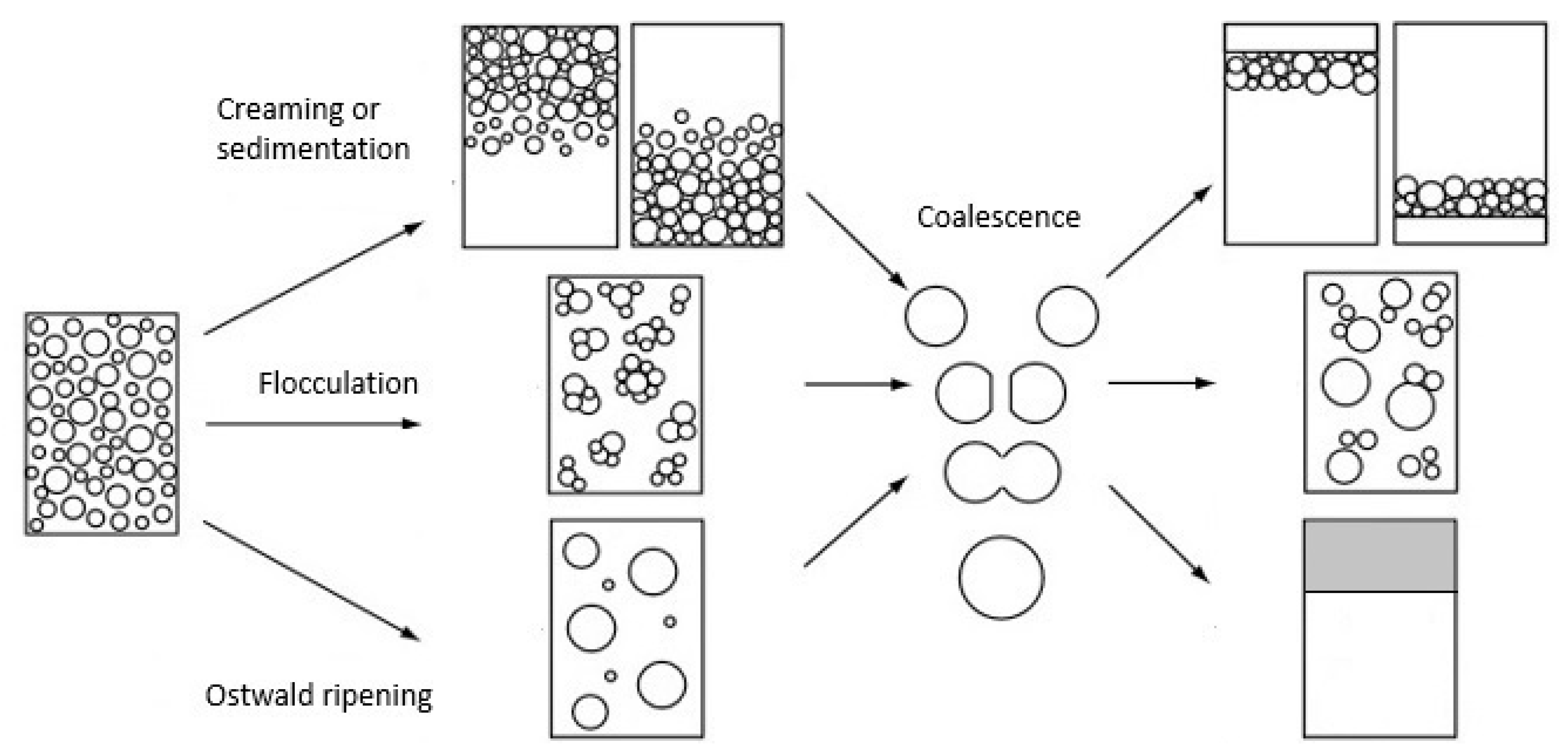

This may include premixing a thickener such as xanthan gum with glycerin, which is then added to the water and other ingredients. Many cosmetic emulsions are oil in water (o/w), where the oil phase is surrounded by the water phase, but there are many examples of water in oil (w/o) emulsions as well.Ī typical emulsion mixing process begins with heating the water phase and water soluble ingredients to 75‑80☌, depending on the procedure. Emulsion Mixing with Cosmetics Introductionįor many cosmetic formulators, the terms lotion and cream are interchangeable, as both involve mixing to create an emulsion.

0 kommentar(er)

0 kommentar(er)